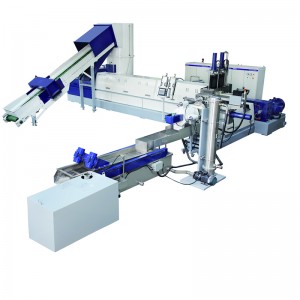

Magawo awiri mapulasitiki Mafilimu ndi ulusi ndi matumba Pelletizing makina

Kanema wazogulitsa:

Kukonza Zithunzi Zazida:

Zothandizira:

HDPE, LDPE, LLDPE, PP, monga mafilimu, zikwama, flakes, mafilimu odzigudubuza, filimu yotambasula, filimu yochepetsera, filimu yamitundu yambiri, thumba la T-shirt lodulidwa

Foamed PE, EPS ndi XPS: masikono, thumba, pepala, chidebe cha chakudya, ukonde wa zipatso, chivundikiro

Zovala: PP CHIKWANGWANI, raffia, silika, ulusi, thumba thumba, jumbo thumba

Mawonekedwe:

Dongosolo lophatikizika la compactor iyi limapindula ndi zinthu zobwezerezedwanso popanda kudula

Kuphatikizika kumakhala ndi ma valve odulira, omwe amagwiritsidwa ntchito powongolera liwiro la kudyetsa zinthu

Vacuum system kuti iwononge madzi kapena gasi kwambiri

Zosefera zabwino kwambiri za hydraulic screen zokhala ndi kukakamiza kokhazikika kwa osayimitsa, osatulutsa

Kupulumutsa mphamvu ndi kutulutsa kwakukulu (0.28kwh/kg)

General ntchito:

1.Belt conveyor kutengerapo zinthu mu shredding compactor.

2.The interlock control system pakati pa lamba kufikitsa ndi shredding compactor amaonetsetsa kudyetsa bwino popanda compactor wosungunuka.

3.Pansi pa shredding compactor, pali bolodi limodzi lodula.ndi mphamvu yapakati, zinthu zobwezerezedwanso zimadulidwa kale ndi odula amkati ndi odulira osasunthika.

4.Pambuyo pake, zinthu zimapita ku degassing screw kuchokera kumbali ya compactor.

5.Kutentha kwa phula, pulasitiki imakhala zinthu za theka-plastification.

6. Kenako, zinthu za semi-pulasitiki zimadulidwa kukhala ma pellets.

Main Technical Parameter:

| Chitsanzo | ML75 | ML85/SJ90 | ML100/SJ120 | ML130/SJ140 | ML160/SJ180 | ML180/SJ200 |

| Screw diameter (mm) | 75 | Gawo loyamba 85 Gawo lachiwiri 90 | Gawo loyamba 100Second stage 120 | Gawo loyamba:130Gawo lachiwiri:140 | Gawo loyamba:160Gawo lachiwiri:180 | Gawo loyamba:180Gawo lachiwiri:200 |

| L/D | Gawo loyamba: 26 mpaka 37 Gawo lachiwiri: 10 mpaka 15 | |||||

| Zotulutsa (kg/h) | 100-150 | 150-250 | 250-350 | 450-550 | 600-800 | 1000 |

Zithunzi za Makina:

Single screw extruder

Pawiri siteji yobwezeretsanso extruder

Zina zambiri:

| Dzina lachitsanzo | ML |

| zotuluka | Pulasitiki ma pellets/granules/resins/pulasitiki zopangira |

| Zigawo zamakina | Belt conveyor, cutter compactor, main extruder, pelletizing unit, cooling system, silo, cabinet |

| Zobwezeretsanso | PP/PE/LDPE/HDPE filimu, thumba, CHIKWANGWANI |

| Mtundu wa luso | 100kg/h mpaka 1200kg/h |

| Kudyetsa njira | Conveyor, roll drive system |

| Screw diameter | 75mm kuti 200mm |

| Chophimba L/D | 26 ndi33 |

| Pewani zopangira | 38CrMoAl kapena bimetallic |

| degassing | Natural degassing, vacuum degassing |

| Kudula mtundu | Oima pelletizing njira, kukoka Mzere pelletizing |

| Mtundu wozizira | Madzi ozizira, mpweya wozizira |

| Voteji | Zosinthidwa mwamakonda |

| Zosankha zida | Chojambulira zitsulo, njira yozizirira madzi, silo yodyetsera, makina ogwedeza |

| Nthawi yoperekera | Masiku 40 mpaka 60 |

| Nthawi ya chitsimikizo | 13 miyezi |

| Thandizo laukadaulo | Masanjidwe a makina, masanjidwe oyika, ntchito ya injiniya kunja kwa nyanja |

| Satifiketi | CE/ SGS/TUV/CO |

Chifukwa chiyani tisankha ife?

A.PURUI ali ndi akatswiri opanga kuyambira 2006. tili ndi dipatimenti yathu yokonza luso.Aliyense extruder kupeza kupangidwa malinga ndi zinthu mbali.

B.Kupulumutsa mphamvu ndi kutulutsa kwakukulu

C.Quality guaranty time ndi miyezi 12 kuchokera tsiku la Bill of Lading.

D. Nthawi yotumiza: Masiku 40 ogwira ntchito mpaka masiku 60

E.Ship anapempha phukusi

Kuyika kwa F.Machine kulipo.Zimatenga masiku 5 mpaka 7 ndikumaliza nthawi imodzi yoyika.Mainjiniya omwe adapatsidwa amayang'anira maphunziro ogwiritsa ntchito makina, kugwiritsa ntchito makina ndi ntchito.

Chiyambi cha Kampani:

Chengdu PuRui Polima Engineering Co. Ltd ndi mmodzi mwa opanga kutsogolera makina pulasitiki yobwezeretsanso pulasitiki, extruder, pulasitiki granulator ndi zina zida wothandiza ku China.Ubwino wapadera wa makina athu apulasitiki opangira ma pelletizing ndi kapangidwe ka zomangira, kutulutsa kwakukulu, kutulutsa mpweya wabwino komanso zosefera zabwino.Chingwe chathu chochapira cha pulasitiki monga chopukutira chotha kupirira komanso chodula chakuthwa, ma unit ochapira, kulekanitsa kapena kusanja makina, makina owumitsa, ndi makina onyamula ndi abwino kwambiri.

Makina obwezeretsanso pulasitiki ndi ma granulating ndi mtundu wa zida zomwe zimagwiritsidwa ntchito pokonzanso zinyalala za pulasitiki kukhala ma granules kapena ma pellets omwe angagwiritsidwenso ntchito popanga zinthu zapulasitiki zatsopano.Makinawa amagwira ntchito pophwanya kapena kugaya zinyalala zapulasitiki kukhala tiziduswa tating'ono, kenako ndikuzisungunula ndikuzitulutsa kudzera mukufa kuti apange ma pellets kapena ma granules.

Pali mitundu yosiyanasiyana yamakina obwezeretsanso pulasitiki ndi makina opangira granulating omwe alipo, kuphatikiza masikelo amodzi ndi ma twin-screw extruder.Makina ena amakhalanso ndi zina zowonjezera monga zowonetsera kuti achotse zonyansa kuchokera ku zinyalala za pulasitiki kapena machitidwe ozizira kuti zitsimikizidwe kuti ma pellets akhazikika bwino.PET makina ochapira botolo, PP nsalu matumba ochapira mzere

Makina obwezeretsanso pulasitiki ndi granulating amagwiritsidwa ntchito m'mafakitale omwe amapanga zinyalala zambiri zapulasitiki, monga kulongedza, magalimoto, ndi zomangamanga.Pokonzanso zinyalala zapulasitiki, makinawa amathandizira kuchepetsa kuwonongeka kwa chilengedwe ndi kutaya kwa pulasitiki ndikusunga zinthu pogwiritsa ntchito zinthu zomwe zikanatayidwa.

Zida zobwezeretsanso batire la Lithium ndi mtundu wa zida zomwe zimagwiritsidwa ntchito pokonzanso ndikubwezeretsanso zida zamtengo wapatali kuchokera ku mabatire a lithiamu-ion, zomwe zimagwiritsidwa ntchito kwambiri pazida zamagetsi monga mafoni a m'manja, laputopu, ndi magalimoto amagetsi.Zidazi zimagwira ntchito pophwanya mabatire m'zigawo zawo, monga cathode ndi anode, njira ya electrolyte, ndi zojambula zazitsulo, kenako ndikulekanitsa ndi kuyeretsa zinthuzi kuti zigwiritsidwenso ntchito.

Pali mitundu yosiyanasiyana ya zida zobwezeretsanso batire la lithiamu zomwe zilipo, kuphatikiza njira za pyrometallurgical, njira za hydrometallurgical, ndi njira zamakina.Njira za pyrometallurgical zimaphatikizapo kutentha kwambiri kwa mabatire kuti apezenso zitsulo monga mkuwa, nickel, ndi cobalt.Njira za Hydrometallurgical zimagwiritsa ntchito njira zamankhwala kuti zisungunuke zida za batri ndikubwezeretsanso zitsulo, pomwe makina amachitidwe amaphatikizira kuphwanya ndi kugaya mabatire kuti alekanitse zida.

Zipangizo zobwezeretsanso mabatire a lithiamu ndizofunikira pakuchepetsa kuwononga kwachilengedwe kwa mabatire ndikusunga zinthu pobwezeretsanso zitsulo zamtengo wapatali ndi zida zomwe zitha kugwiritsidwanso ntchito mu mabatire atsopano kapena zinthu zina.

Kuphatikiza pazopindulitsa zachilengedwe ndi zosungirako zinthu, zida zobwezeretsanso batire la lithiamu zilinso ndi phindu pazachuma.Kubwezeretsanso zitsulo zamtengo wapatali ndi zipangizo kuchokera ku mabatire ogwiritsidwa ntchito kungachepetse mtengo wopangira mabatire atsopano, komanso kupanga njira zatsopano zopezera ndalama kwa makampani omwe akukhudzidwa ndi ntchito yobwezeretsanso.

Kuphatikiza apo, kufunikira kochulukira kwa magalimoto amagetsi ndi zida zina zamagetsi kukuyendetsa kufunikira kwamakampani obwezeretsanso mabatire oyenera komanso okhazikika.Zida zobwezeretsanso batire la lithiamu zitha kuthandiza kukwaniritsa izi popereka njira yodalirika komanso yotsika mtengo yopezeranso zida zamtengo wapatali kuchokera ku mabatire ogwiritsidwa ntchito.

Komabe, ndikofunikira kuzindikira kuti kukonzanso kwa batire la lithiamu akadali bizinesi yatsopano, ndipo pali zovuta zomwe muyenera kuthana nazo popanga njira zobwezeretsanso bwino komanso zotsika mtengo.Kuphatikiza apo, kusamalira moyenera ndikutaya zinyalala za batri ndikofunikira kuti tipewe ngozi ndi thanzi.Chifukwa chake, malamulo oyenera ndi njira zotetezera ziyenera kukhazikitsidwa kuti zitsimikizire kusamalira ndi kubwezeretsanso mabatire a lithiamu.