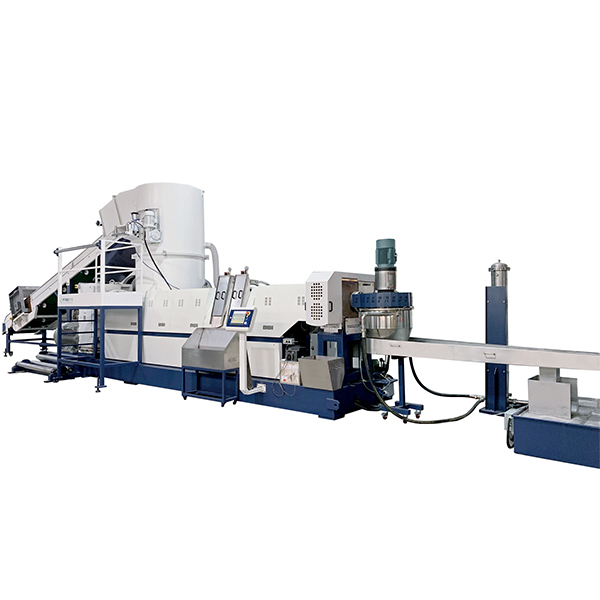

BOPP filimu granulating makina granulation

Makina opangira filimu ya BOPP amaphatikiza ntchito za kuphwanya, kuphatikizika, pulasitiki ndi granulation, ndipo ndi yoyenera kukonzanso pulasitiki ndi njira zopangira granulation.Filamenti ya filimu ya BOPP ndi njira yodalirika komanso yodalirika yopangira filimu yapulasitiki, raffia fiber, filament, thumba, chikwama choluka ndi thovu.Chomaliza chopangidwa ndi filimu ya Fangsheng BOPP granulator / pelletizer ndi mawonekedwe a granules / granules, zomwe zingathe kuikidwa mwachindunji mu mzere wopangira mafilimu, kutulutsa chitoliro ndi jekeseni wa pulasitiki, ndi zina zotero.

Makinawa ndi amtundu wa makina obwezeretsanso pulasitiki.Ikhoza kusamutsa zinyalala matrial mu ma pellets othandiza kuti apitirize kupanga.

Mafilimu a BOPP Granulating Machine Features:

1. Makina opangira filimu ya BOPP ali ndi kusinthika kwabwino, pafupifupi mitundu yonse ya granulation wamba ya pulasitiki imatha kusinthidwa.Mphamvu yogwiritsira ntchito mphamvu yamakina obwezeretsanso pulasitiki ndiyotsika.Ubwino wa mankhwala linanena bungwe ndi mabuku mpikisano ubwino ndi zoonekeratu.

2. Kumapeto kwa mbiya wononga, chobwezeretsanso granulator chokhala ndi magawo awiri othamanga osayimitsa chophimba cha hydraulic amatha kusefa bwino dothi la pulasitiki losungunuka.

3. Tizigawo tatsopano pambuyo powomba kapena jekeseni zitha kugwiritsidwa ntchito kupanga zinthu zapulasitiki zatsopano.Mwachitsanzo, mafilimu apulasitiki, matumba apulasitiki, mabotolo apulasitiki, mapepala apulasitiki, mabokosi apulasitiki, migolo yapulasitiki, ndi zina zotero.

4. Njira yogawa mphamvu yodziwikiratu imatengedwa kuti iwonetsetse kuti galimotoyo ikuyenda bwino.

Makanema a BOPP Ogwiritsanso Ntchito Makina Opangira Ma Granulating:

Zabwinobwino:

| Chitsanzo | ML85 | ML100 | Chithunzi cha ML130 | Chithunzi cha ML160 | Chithunzi cha ML180 |

| Zotulutsa (kg/h) | 120-180 | 180-300 | 400-500 | 600-800 | 800-1000 |

Kutulutsa kwakukulu, kugwiritsa ntchito kochepa:

| Chitsanzo | Chithunzi cha ML100B | Chithunzi cha ML130B | Chithunzi cha ML160B | Chithunzi cha ML180B |

| Zotulutsa (kg/h) | 350-400 | 500-600 | 600-800 | 1000-1100 |

Mafilimu a BOPP Obwezeretsanso Makina Ogwiritsa Ntchito Makina Ang'onoang'ono:

filimu ya bopp → chonyamulira lamba → compactor → screw extruder imodzi → hydraulic screen chosinthira → pelletizing system → transmission air → kasungidwe ka silo

Tsatanetsatane wa Zida Zopangira Mafilimu a BOPP:

Water-ring Die-face cutting system

Njira zodulira mphete yamadzi / Strand kudula nthawi zambiri zimatengera.M'madzi-mphete yodulira nkhope yamadzi, masamba odulira mozungulira azikhala okwanira bwino komanso pafupi ndi nkhope yakufa kuti awonetsetse kudula bwino.Kuthamanga kwa rotary kwa masamba kumasinthidwa zokha ndi dongosolo la module malinga ndi kusungunuka kwamphamvu pa nkhope yakufa.

kanema:

Mafunso aliwonse, chonde tilankhule nafe momasuka.

Makina obwezeretsanso pulasitiki ndi ma granulating ndi mtundu wa zida zomwe zimagwiritsidwa ntchito pokonzanso zinyalala za pulasitiki kukhala ma granules kapena ma pellets omwe angagwiritsidwenso ntchito popanga zinthu zapulasitiki zatsopano.Makinawa amagwira ntchito pophwanya kapena kugaya zinyalala zapulasitiki kukhala tiziduswa tating'ono, kenako ndikuzisungunula ndikuzitulutsa kudzera mukufa kuti apange ma pellets kapena ma granules.

Pali mitundu yosiyanasiyana yamakina obwezeretsanso pulasitiki ndi makina opangira granulating omwe alipo, kuphatikiza masikelo amodzi ndi ma twin-screw extruder.Makina ena amakhalanso ndi zina zowonjezera monga zowonetsera kuti achotse zonyansa kuchokera ku zinyalala za pulasitiki kapena machitidwe ozizira kuti zitsimikizidwe kuti ma pellets akhazikika bwino.PET makina ochapira botolo, PP nsalu matumba ochapira mzere

Makina obwezeretsanso pulasitiki ndi granulating amagwiritsidwa ntchito m'mafakitale omwe amapanga zinyalala zambiri zapulasitiki, monga kulongedza, magalimoto, ndi zomangamanga.Pokonzanso zinyalala zapulasitiki, makinawa amathandizira kuchepetsa kuwonongeka kwa chilengedwe ndi kutaya kwa pulasitiki ndikusunga zinthu pogwiritsa ntchito zinthu zomwe zikanatayidwa.

Zida zobwezeretsanso batire la Lithium ndi mtundu wa zida zomwe zimagwiritsidwa ntchito pokonzanso ndikubwezeretsanso zida zamtengo wapatali kuchokera ku mabatire a lithiamu-ion, zomwe zimagwiritsidwa ntchito kwambiri pazida zamagetsi monga mafoni a m'manja, laputopu, ndi magalimoto amagetsi.Zidazi zimagwira ntchito pophwanya mabatire m'zigawo zawo, monga cathode ndi anode, njira ya electrolyte, ndi zojambula zazitsulo, kenako ndikulekanitsa ndi kuyeretsa zinthuzi kuti zigwiritsidwenso ntchito.

Pali mitundu yosiyanasiyana ya zida zobwezeretsanso batire la lithiamu zomwe zilipo, kuphatikiza njira za pyrometallurgical, njira za hydrometallurgical, ndi njira zamakina.Njira za pyrometallurgical zimaphatikizapo kutentha kwambiri kwa mabatire kuti apezenso zitsulo monga mkuwa, nickel, ndi cobalt.Njira za Hydrometallurgical zimagwiritsa ntchito njira zamankhwala kuti zisungunuke zida za batri ndikubwezeretsanso zitsulo, pomwe makina amachitidwe amaphatikizira kuphwanya ndi kugaya mabatire kuti alekanitse zida.

Zipangizo zobwezeretsanso mabatire a lithiamu ndizofunikira pakuchepetsa kuwononga kwachilengedwe kwa mabatire ndikusunga zinthu pobwezeretsanso zitsulo zamtengo wapatali ndi zida zomwe zitha kugwiritsidwanso ntchito mu mabatire atsopano kapena zinthu zina.

Kuphatikiza pazopindulitsa zachilengedwe ndi zosungirako zinthu, zida zobwezeretsanso batire la lithiamu zilinso ndi phindu pazachuma.Kubwezeretsanso zitsulo zamtengo wapatali ndi zipangizo kuchokera ku mabatire ogwiritsidwa ntchito kungachepetse mtengo wopangira mabatire atsopano, komanso kupanga njira zatsopano zopezera ndalama kwa makampani omwe akukhudzidwa ndi ntchito yobwezeretsanso.

Kuphatikiza apo, kufunikira kochulukira kwa magalimoto amagetsi ndi zida zina zamagetsi kukuyendetsa kufunikira kwamakampani obwezeretsanso mabatire oyenera komanso okhazikika.Zida zobwezeretsanso batire la lithiamu zitha kuthandiza kukwaniritsa izi popereka njira yodalirika komanso yotsika mtengo yopezeranso zida zamtengo wapatali kuchokera ku mabatire ogwiritsidwa ntchito.

Komabe, ndikofunikira kuzindikira kuti kukonzanso kwa batire la lithiamu akadali bizinesi yatsopano, ndipo pali zovuta zomwe muyenera kuthana nazo popanga njira zobwezeretsanso bwino komanso zotsika mtengo.Kuphatikiza apo, kusamalira moyenera ndikutaya zinyalala za batri ndikofunikira kuti tipewe ngozi ndi thanzi.Chifukwa chake, malamulo oyenera ndi njira zotetezera ziyenera kukhazikitsidwa kuti zitsimikizire kusamalira ndi kubwezeretsanso mabatire a lithiamu.